Industry news

How to Use Polycarboxylate Superplasticizer Powder for Optimal Concrete Results

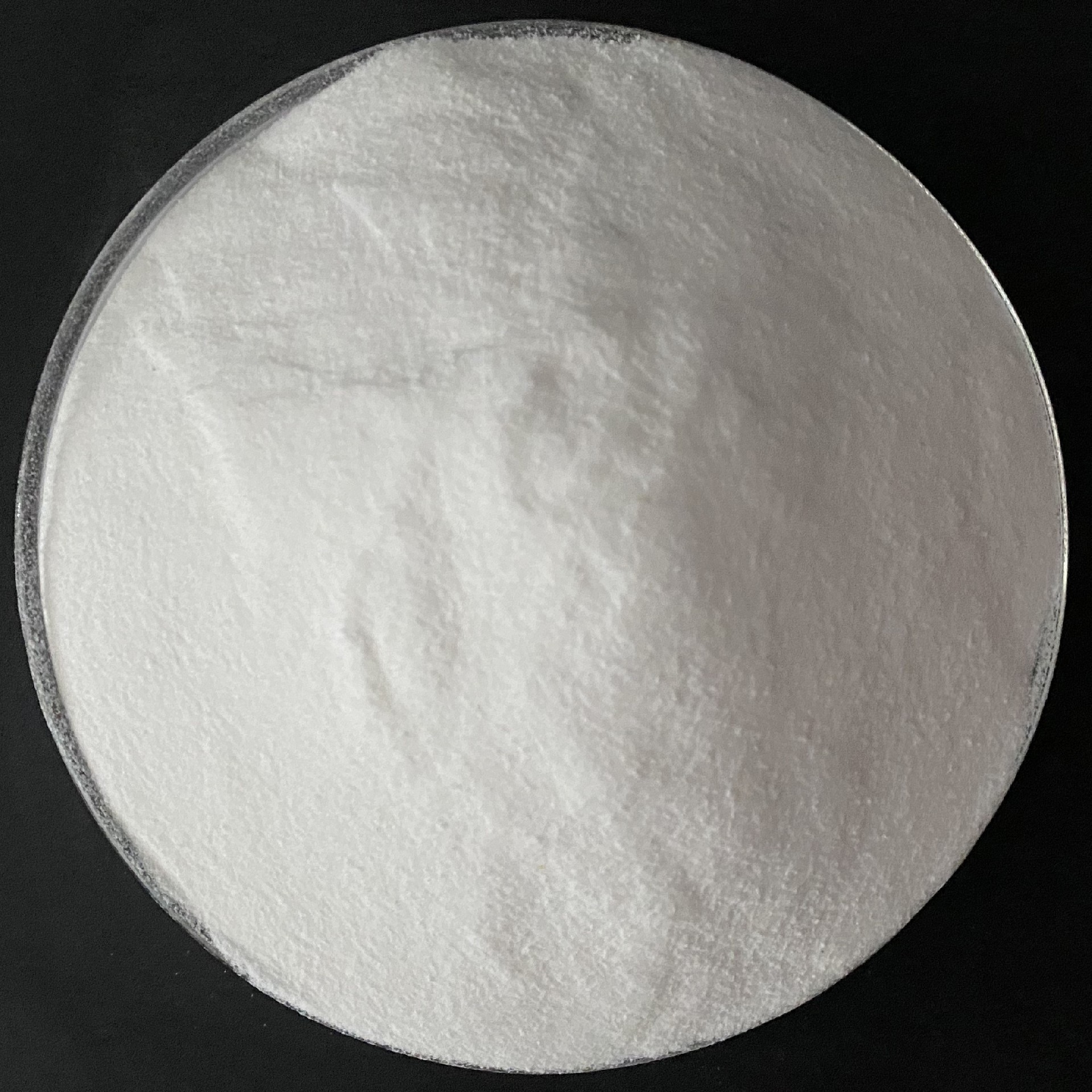

Polycarboxylate superplasticizer powder represents a major leap in concrete technology. This high-range water reducer transforms modern mix designs. Achieving optimal results demands a precise understanding of its application. Proper use unlocks unparalleled strength, durability, and workability. Incorrect use can lead to challenges. This guide details the best practices for success.

Understanding Polycarboxylate superplasticizer Superplasticizer Powder

Polycarboxylate superplasticizer powder is a sophisticated chemical admixture. Its unique molecular structure allows exceptional water reduction. Unlike older admixtures, Polycarboxylate superplasticizer offers superior slump retention. It works by dispersing cement particles effectively. This action frees trapped water within the mix. Consequently, you achieve highly fluid concrete without extra water. The result is high-strength, durable concrete with a excellent finish.

Precision in Dosing is Non-Negotiable

You must determine the correct dosage carefully. This depends on several key factors. Consider the desired slump flow and required strength. Account for cement type and other mix components. Ambient temperature also plays a crucial role. Always follow the manufacturer's specific recommendations. Typical dosage ranges from 0.1% to 0.3% by cement weight. Never guess the amount; precision is critical.

Start with a trial batch for every new project. This practice confirms the ideal dosage. It helps you avoid under-dosing or over-dosing. Under-dosing fails to provide the desired workability. Over-dosing can cause excessive retardation or segregation. Careful testing ensures perfect performance on the job site.

Mastering the Mixing Sequence

The addition sequence profoundly impacts performance. Incorporate the powder correctly for full effectiveness. Always add the Polycarboxylate superplasticizer powder after the initial mix water. Let it dissolve completely during the mixing cycle. This ensures uniform dispersion throughout the concrete. Never add the dry powder directly to dry cement. This can cause balling and inefficient dispersion.

A common best practice involves dissolving it first. You can pre-dissolve the powder in a portion of the mixing water. Create a homogeneous solution before batching. Then add this solution during the normal mixing process. This method guarantees even distribution and maximizes efficiency.

Accounting for Mix Design and Temperature

Polycarboxylate superplasticizer superplasticizers interact with all mix materials. Be mindful of your cement's chemistry and fineness. Some supplementary materials may affect performance. Test the mix with local materials beforehand. Temperature significantly influences concrete behavior. Hot weather accelerates slump loss. You might need a slightly adjusted dosage. Cold weather can slow the setting time. Understand these environmental interactions.

Achieving Specific Concrete Properties

Use Polycarboxylate superplasticizer powder to tailor concrete for specific applications.

For High-Strength Concrete: Utilize its powerful water-reducing capability. Significantly lower the water-cement ratio. This dramatically increases compressive strength. Produce durable, dense concrete with minimal permeability.

For Self-Consolidating Concrete (SCC): Rely on its excellent plasticizing effect. Achieve high flowability without segregation. The concrete should fill every part of the formwork easily. It eliminates the need for mechanical vibration.

For Improved Workability and Finish: Enhance the concrete's placement experience. Enjoy extended slump life for easier handling. Produce smooth, high-quality surface finishes with minimal effort.

Avoiding Common Application Mistakes

Steer clear of these frequent errors for best results.

Avoid adding the powder too late in the mixing cycle. Inconsistent dispersion will result. Do not use outdated or lumpy powder. Its effectiveness diminishes over time. Always store it in a cool, dry place. Never compensate for a poor mix design with extra admixture. First, optimize the aggregate gradation and cement content.

Remember that Polycarboxylate superplasticizer is a powerful tool. More is not always better. Excessive addition can lead to severe segregation. The paste may separate from the aggregates. Carefully monitor the concrete's consistency during placement.

Conclusion: Unlocking Superior Performance

Polycarboxylate superplasticizer powder empowers concrete professionals. It enables the creation of high-performance mixes previously thought impossible. Success hinges on meticulous dosing and proper batching. Respect the mixing sequence and environmental conditions. Always conduct preliminary trials with your materials. You will then consistently produce exceptional concrete. Embrace this advanced technology to build stronger, more durable, and efficient structures.

RELATED NEWS

- Polycarboxylate Superplasticizer Liquid: Elevate Your Concrete, Cut Costs2026-03-02

- Polycarboxylate Superplasticizer Dosage Tips: Optimizing Flowability for Winter Concrete Work2025-11-06

- Naphthalene Based Superplasticizer: Dosage Recommendations for Concrete Mixes2025-09-30

- How to Use Polycarboxylate Superplasticizer Powder for Optimal Concrete Results2025-09-23

CATEGORIES

LATEST NEWS

- Polycarboxylate Superplasticizer Liquid: Elevate Your Concrete, Cut Costs

- Polycarboxylate Superplasticizer to the Peru

- Polycarboxylate Superplasticizer Dosage Tips: Optimizing Flowability for Winter Concrete Work

- Binzhou Chengli Shines at 2025 Moscow Cement Exhibition: Showcasing Superplasticizers & Securing Sample Tests

- concrete admixtures manufacturer in china:Binzhou Chengli Building Materials Co., Ltd.

CONTACT US

Phone: +86 543-3324448

Tel: +86 543-3324448

Email: chengli@chenglicn.com

Add: 137-7# Yongxin Rd,Bincheng District,Binzhou City Shandong Province,China